Cutting tables

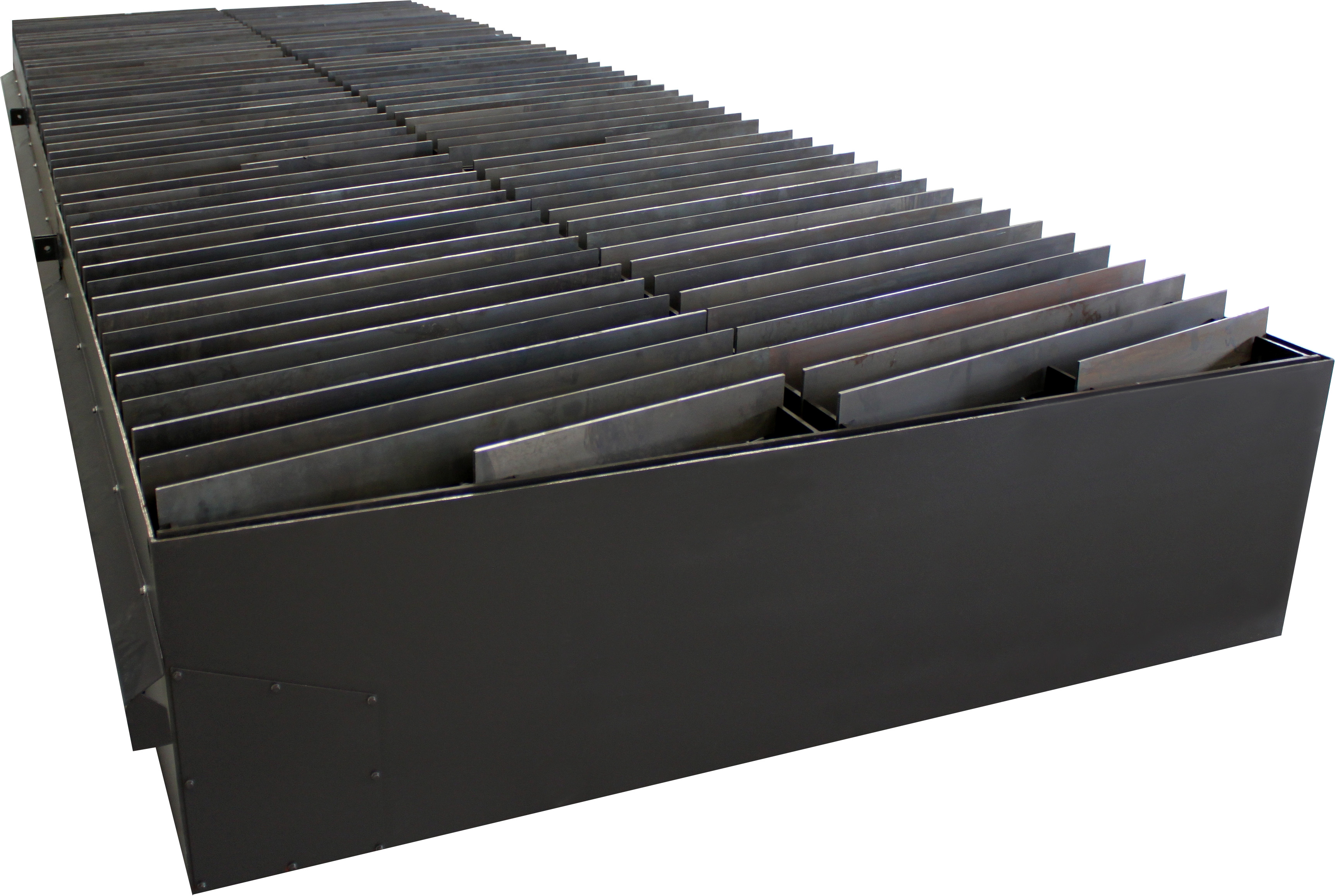

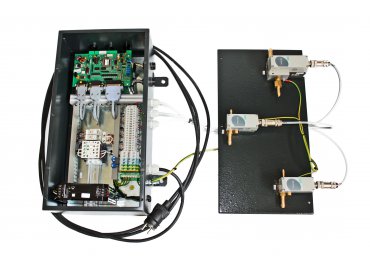

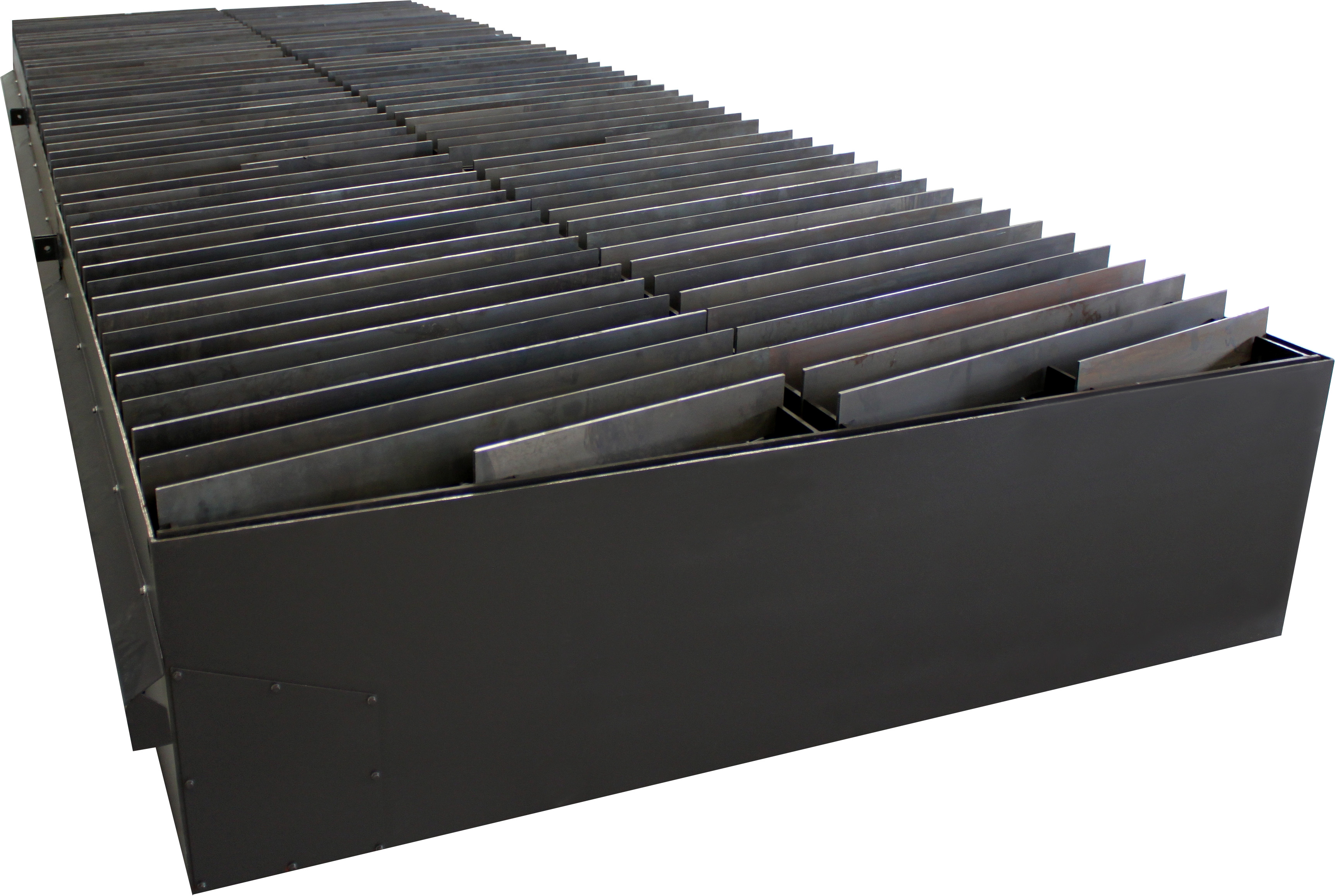

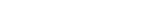

Cutting table is used for placement of material that is cut by oxyacetylene or plasma burner. At the same time It is used for exhaust of combustion products and dust created during the execution of these processes. High rigidity, corresponding load bearing capacity, resistance against heat created during the cutting process and simple handling during removal of created wastes are fundamental design requirements for the table. An effective exhaust of the combustion products protects health of cutting machine operators and It also prevents deposition of fine metal dust on the machine Itself as well as on the surrounding devices. It increases their service life substantially. Quality and reliable exhaust is secured by special design of the table, which enables even exhaust of generated combustion products from Its upper part. The design also reduces direct entering of hot parts into the sucking channel of the table. Modular design of the table enables simple change of individual part of system in case of damage or wearing.

We offer to our customers PIERCE cutting tables in 5 options and various dimensions:

SPECIFICATION NO.1

| Model of table |

Cutting method |

Max. plasma current, A |

Max. loading Kg/m² |

Max. air channels |

Pneumatic lines, material |

| LIGHT |

| Light |

Plasma |

105 |

250 |

1 |

PVC |

| Light plus |

Plasma |

130 |

390 |

1 |

PVC |

| STANDARD |

| Standard plus |

Plasma /Flame |

300 |

1600 |

2 |

PVC + Copper |

| HEAVY |

| Heavy |

Plasma /Flame |

440 |

2000 |

2 |

PVC + Copper |

| Heavy plus |

Plasma /Flame |

800 |

2400 |

2 |

PVC + Copper |

SPECIFICATION NO.2

| Model of table |

Max. thickness of material, mm |

Table wall thickness, mm |

Section width, mm |

Width of module range, mm |

Length range, mm |

| Plasma |

Oxy |

| LIGHT |

| Light |

22 |

- |

3 |

515 |

1000-1500 |

1000-3000 |

| Light plus |

40 |

- |

4 |

515 |

1000-2600 |

1000-12000 |

| STANDARD |

| Standard plus |

70 |

200 |

5 |

515 |

1500-3100 |

2000-no limit* |

| HEAVY |

| Heavy |

120 |

250 |

6 |

515 |

2000-3100 |

2000-no limit* |

| Heavy plus |

160 |

300 |

6 |

515 |

2000-3100 |

2000-no limit* |

* Longitudinal module docking